Plasma box

Choose Plasmabox for pinhole free, high purity films and simple reactor maintenance

Test Modal

Ullenda voluptaspe natem. Ceped quam rem. Nemped que porehen ihilitatis quas endest etur alis as id quatium expelic imoluptatur repe dendere ribus, sam nonserferum nessit que vel maxim re porro od quam dolo dusaectore aperuptae qui volore, comnisquo tem incto blacepu digniet pra dit labo. Tis aspid et everfer ovidestis derro tem sedis eicabo. Optaspe rferia volesenes erro quam, sitatus solut quiatum res same atem hitiam vento is videbit velit deror autatem.

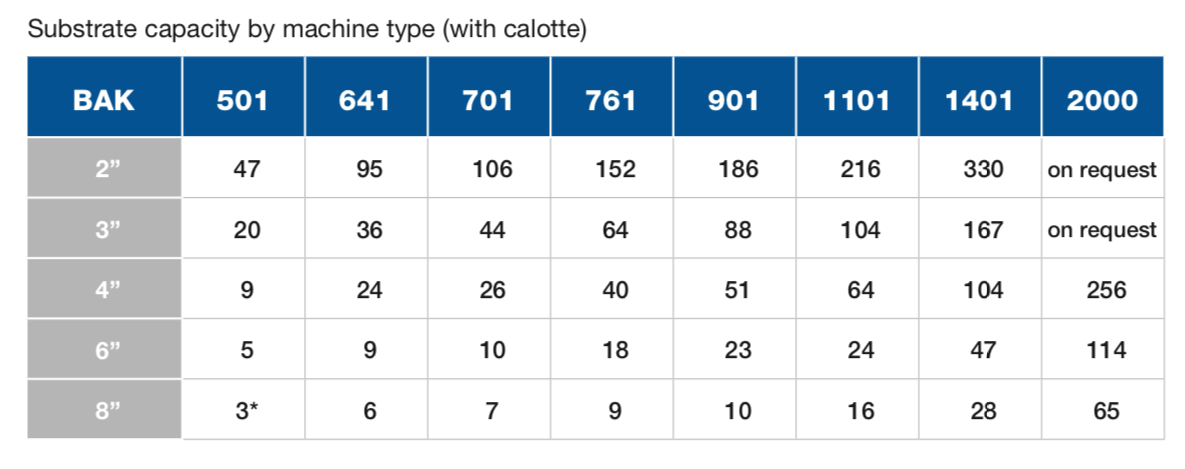

From the smallest to the biggest- get an idea how many substrates our systems can hold in a single batch

PECVD

PLASMABOX® technology for high quality coatings at low temperature

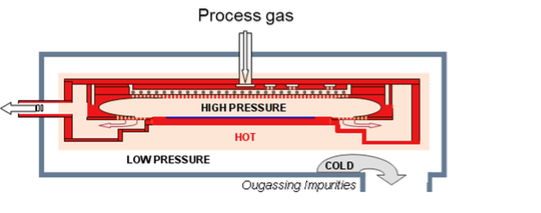

The production proven PLASMABOX® concept means we can improve film properties for special applications and reduce cross contamination due to differential pumping and in-situ cleaning. With the pressure difference and the colder outer chamber wall we keep away outgassing impurities from the process chamber, which improves the film quality. Our PECVD processes run at lower temperatures compared with other PECVD or CVD systems which brings some great opportunities:

- Flexible concept, open for customization

- Modular chuck design for fast size conversion

- Very high film purity, better than standard parallel plate design

- Outstanding thickness uniformity (1.5% (1sigma) on 8”) and layer properties

- In-situ cleaning with SF6 or other gases

- Dual pressure gauge (process / cleaning)

- Stress tuning capability (tensile / compressive)

- Tunable refractive index

- Pinhole free films with high breakdown voltages

To learn more about our know-how and platforms click on the individual tabs or click here to contact us.

Evatec PLASMABOX® process knows how to deliver deposition processes for layers including SiO2, SiN, SiOxNy, SiOF, α-Si using process gases including NH3, SiH4, H2, Ar, He, N2O, N2, SF6, O2, N2, and SiF4.

Click here to see a cross section of PLASMABOX®

PECVD Platforms

PECVD technology using PLASMABOX® is available on Evatec's production proven CLUSTERLINE® 200 platform.

Our experts are on hand to help you so please just contact us if you have questions. Alternatively, click on the photo link to read more.

CLUSTERLINE® 200

Semiconductor industry standard cluster platform for 200mm single substrate processing integrating modules for ICP etch, PVD and PECVD.

The production proven PLASMABOX® concept means we can improve film properties for special applications and reduce cross contamination due to differential pumping and in-situ cleaning. With the pressure difference and the colder outer chamber wall we keep away outgassing impurities from the process chamber, which improves the film quality. Our PECVD processes run at lower temperatures compared with other PECVD or CVD systems which brings some great opportunities:

- Flexible concept, open for customization

- Modular chuck design for fast size conversion

- Very high film purity, better than standard parallel plate design

- Outstanding thickness uniformity (1.5% (1sigma) on 8”) and layer properties

- In-situ cleaning with SF6 or other gases

- Dual pressure gauge (process / cleaning)

- Stress tuning capability (tensile / compressive)

- Tunable refractive index

- Pinhole free films with high breakdown voltages

To learn more about our know-how and platforms click on the individual tabs or click here to contact us.

Evatec PLASMABOX® process knows how to deliver deposition processes for layers including SiO2, SiN, SiOxNy, SiOF, α-Si using process gases including NH3, SiH4, H2, Ar, He, N2O, N2, SF6, O2, N2, and SiF4.

Click here to see a cross section of PLASMABOX®

PECVD Platforms

PECVD technology using PLASMABOX® is available on Evatec's production proven CLUSTERLINE® 200 platform.

Our experts are on hand to help you so please just contact us if you have questions. Alternatively, click on the photo link to read more.