Plasma box

Choose Plasmabox for pinhole free, high purity films and simple reactor maintenance

Test Modal

Ullenda voluptaspe natem. Ceped quam rem. Nemped que porehen ihilitatis quas endest etur alis as id quatium expelic imoluptatur repe dendere ribus, sam nonserferum nessit que vel maxim re porro od quam dolo dusaectore aperuptae qui volore, comnisquo tem incto blacepu digniet pra dit labo. Tis aspid et everfer ovidestis derro tem sedis eicabo. Optaspe rferia volesenes erro quam, sitatus solut quiatum res same atem hitiam vento is videbit velit deror autatem.

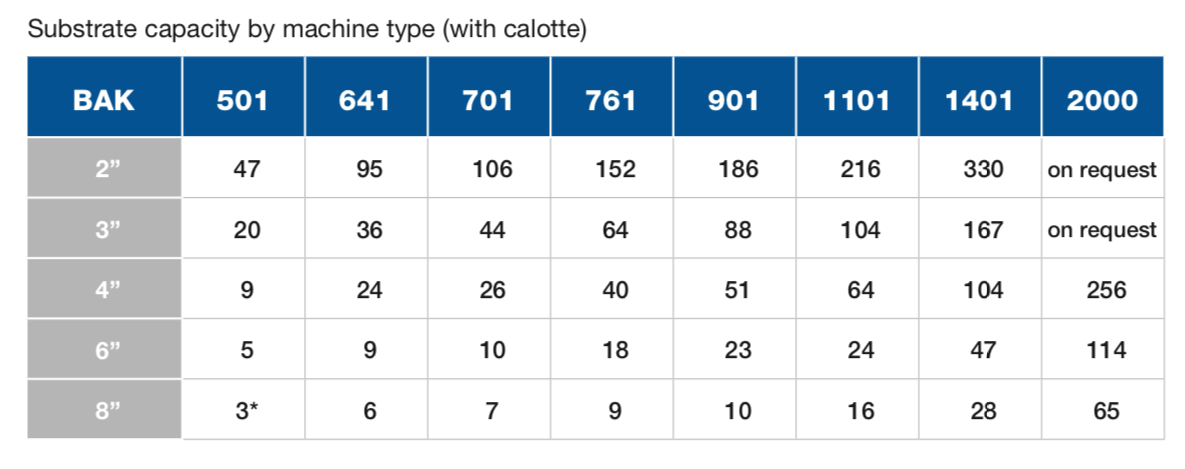

From the smallest to the biggest- get an idea how many substrates our systems can hold in a single batch

ADVANCED PROCESS CONTROL (APC)

“Raising the bar” in thin film processes

Why Advanced Process Control?

APC brings semiconductor industry manufacturing precision to the production of next generation "wafer level optics" for 3D Sensing and Face Recognition in smart phones or the layer control techniques used for critical optical processes to control the refractive index, thickness and surface quality of the layers required for the next generation of RF devices and solid state lighting.

Find out how Evatec's quartz and optical monitoring with "in Situ" Reoptimization offer superior production control in deposition of precious metals and complex dielectric stacks on high value substrates.

Stoichiometry Control

From co-evaporation of metal alloys to sputter of dielectric layers we offer control technologies to ensure the correct stoichiometry and refractive index at the highest deposition rates.

Film Stress Measurement

Available on both our evaporation and sputter tools, using the know how gained from "in situ" stress measurement enables management of bending during deposition on thin wafers and optical substrates or the deposition of thick stacks without cracking.

Unicalc shaper modelling reduces your materials costs and increases your throughputs in evaporation processes on our BAK platform.

Thermal Management

Evatec closed loop temperature control ensures processes are optimized and substrates protected from damage.

Target & Shield Life

Evatec know-how delivers extended target and shield life for maximum production output and lowest cost of ownership.

Advanced Process Control Technologies are available across different Evatec production platforms according to application. To learn more about some of the individual techniques click on the individual tabs or click here to contact us.

Quartz Monitoring

Control deposition rate and layer thicknesses accurately and reliably across a wide range of evaporation processes. Evatec's own new QCM 500 controller offers improved accuracy, faster switching time between crystals, 5 or 6MHz operation and multiple head management from a single controller. The QSK621 quartz head is an ideal solution for many evaporation processes on the BAK platform. Full Khan integration handles used-up crystal mid process with ease switching to back up crystals and ensuring batch evaporation processes can be completed without loss. For thicker layers and more complex processes a 12 crystal head is available for integration in new systems or for retrofit.

The QSK300 single head can be installed for single source monitoring in co-evaporation processes and both single and multiway heads can be fitted with chopper technology for control of extended layer thicknesses or longer crystal lifetimes.

Optical Monitoring

From the high reflectivity DBR mirrors required for maximizing light output in our HBLEDS to the new 3D sensing & face recognition technologies for our next generation smart phones, our world relies on the cost effective deposition of accurate optical interference coatings. Within our next generation mobile networks and power devices too, thin film processes increasingly call for deposition of custom dielectric stacks at accuracies which traditional control techniques can't achieve.

With GSM1101 versatility comes as standard. It uses direct measurement of film optical performance in the UV, VIS or NIR wavelength range as a control technique. It can be configured for monochromatic or broadband operation or using a combination of both (i.e. “hybrid mode”). It can measure either reflectance or transmittance on the actual substrates or indirectly on test glasses and can be integrated in a broad range of Evatec's evaporation or sputter platforms. The GSM1101 is also able to measure and analyse deposited multilayer stacks for closed-loop control in in-line deposition systems.

Here are just a few GSM1101 benefits

- enhanced accuracy and repeatability

- layer-by-layer spectral measurement data for process analysis

- In-situ reoptimisation technology for higher yields

- control of ultra thin metal layers

- closed-loop thickness control in in-line deposition systems

To download the GSM optical monitoring brochure click here.

Stoichiometry Control

Fully automated active recipe adjustments mid process can improve your yields in high precision optical coatings. In-situ reoptimisation is a powerful and efficient tool that reviews your optical thin film deposition processes as they happen, adjusting remaining layers to ensure the final optical film stack is exactly as you intended. Use it to eliminate scrap in case of unexpected process interruption by recovering your process, save process development time for new designs and enhance your yields.

Evatec closed loop process control technologies enable coatings with precise stoichiometry control in both evaporation and sputter deposition processes. Based on live monitoring systems, the desired film composition is met in a reliable and reproducible way. Innovative solutions allow for short process times required in high-volume manufacturing.

Sputter Deposition

Deposit oxide and nitride layers of excellent quality at high rates. We use advanced Plasma Emission Monitoring (PEM) technology to ensure delivery of correct stoichiometry and high rates in deposition of dielectrics and TCOs on our range of batch and cluster reactive magnetron sputter deposition platforms. The intensity of one or multiple characteristic plasma emission peaks as well as other process parameters are monitored.

The ideal working point of any metal oxide or nitride process is determined through dedicated knowledge. This reactive deposition working point is then maintained throughout the complete process duration. Process times are thereby shortened while excellent film properties are maintained. Problems of drifts, arcing (particles), and reduced uptime due to poisoning of the target are eliminated. The robust feedback loop architecture and the fast response times of the reactive gas inlet make our PEM technology an essential component for dielectric thin film production.

Evaporation

Interested in thin films composed of different materials? Closed loop quartz monitoring of up to 4 individual sources using Evatec's own QCM500 quartz controller delivers accurate deposition of alloys from boat, e gun, or effusion cell sources in our range of BAK Evaporators. Our quartz crystal based rate monitoring system is an integral part of the BAK platform, facilitating advanced strategies for mixing multiple materials and controlling thickness uniformities across the batch, for instance.

In Situ Reoptimization

Fully automated active recipe adjustments mid process can improve your yields in high precision optical coatings. In-situ reoptimization is a powerful and efficient tool that reviews your optical thin film deposition processes as they happen, adjusting remaining layers to ensure the final optical film stack is exactly as you intended. Use it to eliminate scrap in case of unexpected process interruption by recovering your process, save process development time for new designs and enhance your yields.

To view the reoptimization brochure click here

In Situ Reoptimization benefits

- Fully automated process, no increase in process times

- Optimizes yields for complex stack designs

- Recovers production batches after unexpected process interruptions

- Available on BAK Evaporator, MSP Sputter and CLUSTERLINE® 200 Sputter Cluster Platforms with Evatec Optics Tool Box

- Available for double sided optical coatings using flip tooling

- Available for analysis of deposited multilayers and closed-loop feedback on SOLARIS® and CLUSTERLINE® 200 platforms

The Reoptimization loop

Real time optimization uses in situ GSM Broadband Optical Monitoring not just during the deposition of every layer to determine end point but also at the end of every layer. The actual optical performance after layer termination is compared with the precalculated and in the case of deviation greater than levels set by you the remaining coating recipe is adjusted to bring the process back on track. Reoptimization is repeated after each and every layer until the whole stack is complete. View or download the brochure to see the results

Optics Tool Box

The perfect tool to integrate steps in development of your thin film processes Optics Tool Box makes your life simple. It integrates all your optical thin film development processes from initial design, through strategy development for optimum termination of each layer, generation of the actual coating recipe and finally coating execution itself on the coating tool. It is available for our BAK evaporation and MSP or CLUSTERLINE® 200 BPM Sputter Platforms.

Optics Tool Box benefits

- Work with industry standard thin film design software (FilmstarTM, OptilayerTM, or Essential MacleodTM)

- Eliminate errors in process recipe set-up by seamless integration

- Reduce set up costs and increase throughput

- Conveniently manage, analyse and compare optical monitoring data of each layer of all your process runs

Need to develop complex coatings in quick time or work with tight tolerances?

Now our systems check the optical performance in situ after every layer with our GSM Optical Monitor and adjust the downstream process to ensure the final optical stack performance matches theoretical design even more closely. See how you can save time and costs with "In situ reoptimization". Click here to read more about GSM optical monitoring / in situ reoptimisation

Why Advanced Process Control?

APC brings semiconductor industry manufacturing precision to the production of next generation "wafer level optics" for 3D Sensing and Face Recognition in smart phones or the layer control techniques used for critical optical processes to control the refractive index, thickness and surface quality of the layers required for the next generation of RF devices and solid state lighting.

Find out how Evatec's quartz and optical monitoring with "in Situ" Reoptimization offer superior production control in deposition of precious metals and complex dielectric stacks on high value substrates.

Stoichiometry Control

From co-evaporation of metal alloys to sputter of dielectric layers we offer control technologies to ensure the correct stoichiometry and refractive index at the highest deposition rates.

Film Stress Measurement

Available on both our evaporation and sputter tools, using the know how gained from "in situ" stress measurement enables management of bending during deposition on thin wafers and optical substrates or the deposition of thick stacks without cracking.

Unicalc shaper modelling reduces your materials costs and increases your throughputs in evaporation processes on our BAK platform.

Thermal Management

Evatec closed loop temperature control ensures processes are optimized and substrates protected from damage.

Target & Shield Life

Evatec know-how delivers extended target and shield life for maximum production output and lowest cost of ownership.

Advanced Process Control Technologies are available across different Evatec production platforms according to application. To learn more about some of the individual techniques click on the individual tabs or click here to contact us.

Quartz Monitoring

Control deposition rate and layer thicknesses accurately and reliably across a wide range of evaporation processes. Evatec's own new QCM 500 controller offers improved accuracy, faster switching time between crystals, 5 or 6MHz operation and multiple head management from a single controller. The QSK621 quartz head is an ideal solution for many evaporation processes on the BAK platform. Full Khan integration handles used-up crystal mid process with ease switching to back up crystals and ensuring batch evaporation processes can be completed without loss. For thicker layers and more complex processes a 12 crystal head is available for integration in new systems or for retrofit.

The QSK300 single head can be installed for single source monitoring in co-evaporation processes and both single and multiway heads can be fitted with chopper technology for control of extended layer thicknesses or longer crystal lifetimes.

Optical Monitoring

From the high reflectivity DBR mirrors required for maximizing light output in our HBLEDS to the new 3D sensing & face recognition technologies for our next generation smart phones, our world relies on the cost effective deposition of accurate optical interference coatings. Within our next generation mobile networks and power devices too, thin film processes increasingly call for deposition of custom dielectric stacks at accuracies which traditional control techniques can't achieve.

With GSM1101 versatility comes as standard. It uses direct measurement of film optical performance in the UV, VIS or NIR wavelength range as a control technique. It can be configured for monochromatic or broadband operation or using a combination of both (i.e. “hybrid mode”). It can measure either reflectance or transmittance on the actual substrates or indirectly on test glasses and can be integrated in a broad range of Evatec's evaporation or sputter platforms. The GSM1101 is also able to measure and analyse deposited multilayer stacks for closed-loop control in in-line deposition systems.

Here are just a few GSM1101 benefits

- enhanced accuracy and repeatability

- layer-by-layer spectral measurement data for process analysis

- In-situ reoptimisation technology for higher yields

- control of ultra thin metal layers

- closed-loop thickness control in in-line deposition systems

To download the GSM optical monitoring brochure click here.

Stoichiometry Control

Fully automated active recipe adjustments mid process can improve your yields in high precision optical coatings. In-situ reoptimisation is a powerful and efficient tool that reviews your optical thin film deposition processes as they happen, adjusting remaining layers to ensure the final optical film stack is exactly as you intended. Use it to eliminate scrap in case of unexpected process interruption by recovering your process, save process development time for new designs and enhance your yields.

Evatec closed loop process control technologies enable coatings with precise stoichiometry control in both evaporation and sputter deposition processes. Based on live monitoring systems, the desired film composition is met in a reliable and reproducible way. Innovative solutions allow for short process times required in high-volume manufacturing.

Sputter Deposition

Deposit oxide and nitride layers of excellent quality at high rates. We use advanced Plasma Emission Monitoring (PEM) technology to ensure delivery of correct stoichiometry and high rates in deposition of dielectrics and TCOs on our range of batch and cluster reactive magnetron sputter deposition platforms. The intensity of one or multiple characteristic plasma emission peaks as well as other process parameters are monitored.

The ideal working point of any metal oxide or nitride process is determined through dedicated knowledge. This reactive deposition working point is then maintained throughout the complete process duration. Process times are thereby shortened while excellent film properties are maintained. Problems of drifts, arcing (particles), and reduced uptime due to poisoning of the target are eliminated. The robust feedback loop architecture and the fast response times of the reactive gas inlet make our PEM technology an essential component for dielectric thin film production.

Evaporation

Interested in thin films composed of different materials? Closed loop quartz monitoring of up to 4 individual sources using Evatec's own QCM500 quartz controller delivers accurate deposition of alloys from boat, e gun, or effusion cell sources in our range of BAK Evaporators. Our quartz crystal based rate monitoring system is an integral part of the BAK platform, facilitating advanced strategies for mixing multiple materials and controlling thickness uniformities across the batch, for instance.

In Situ Reoptimization

Fully automated active recipe adjustments mid process can improve your yields in high precision optical coatings. In-situ reoptimization is a powerful and efficient tool that reviews your optical thin film deposition processes as they happen, adjusting remaining layers to ensure the final optical film stack is exactly as you intended. Use it to eliminate scrap in case of unexpected process interruption by recovering your process, save process development time for new designs and enhance your yields.

To view the reoptimization brochure click here

In Situ Reoptimization benefits

- Fully automated process, no increase in process times

- Optimizes yields for complex stack designs

- Recovers production batches after unexpected process interruptions

- Available on BAK Evaporator, MSP Sputter and CLUSTERLINE® 200 Sputter Cluster Platforms with Evatec Optics Tool Box

- Available for double sided optical coatings using flip tooling

- Available for analysis of deposited multilayers and closed-loop feedback on SOLARIS® and CLUSTERLINE® 200 platforms

The Reoptimization loop

Real time optimization uses in situ GSM Broadband Optical Monitoring not just during the deposition of every layer to determine end point but also at the end of every layer. The actual optical performance after layer termination is compared with the precalculated and in the case of deviation greater than levels set by you the remaining coating recipe is adjusted to bring the process back on track. Reoptimization is repeated after each and every layer until the whole stack is complete. View or download the brochure to see the results

Optics Tool Box

The perfect tool to integrate steps in development of your thin film processes Optics Tool Box makes your life simple. It integrates all your optical thin film development processes from initial design, through strategy development for optimum termination of each layer, generation of the actual coating recipe and finally coating execution itself on the coating tool. It is available for our BAK evaporation and MSP or CLUSTERLINE® 200 BPM Sputter Platforms.

Optics Tool Box benefits

- Work with industry standard thin film design software (FilmstarTM, OptilayerTM, or Essential MacleodTM)

- Eliminate errors in process recipe set-up by seamless integration

- Reduce set up costs and increase throughput

- Conveniently manage, analyse and compare optical monitoring data of each layer of all your process runs

Need to develop complex coatings in quick time or work with tight tolerances?

Now our systems check the optical performance in situ after every layer with our GSM Optical Monitor and adjust the downstream process to ensure the final optical stack performance matches theoretical design even more closely. See how you can save time and costs with "In situ reoptimization". Click here to read more about GSM optical monitoring / in situ reoptimisation