Step 1: Check what system capacity you need

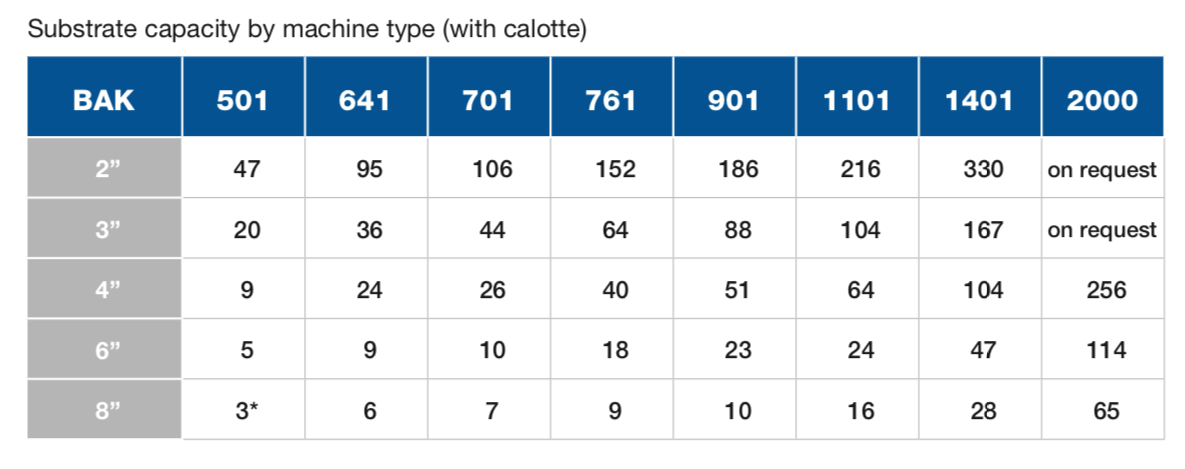

Start by selecting a basic platform size according to your substrate size and preferred batch capacity for standard calotte handling. Click here to view a capacity chart for different system sizes.

Step 2: Choose your sources, accessories and process control technologies

To take a quick look at our portfolio of sources and process accessories click here - from effusion cells and digital beam sweep electron beam guns, to chamber heating and plasma sources for PIAD.

To read more about Evatec advanced process control technologies including quartz and optical monitoring click here

Step 3: Customize your BAK according to your processes and fab integration requirements

Investigate further custom options to build a BAK that’s just right for you.

- "Lift Off" platforms with extended throw for zero side wall coverage

- "Split Chamber" platforms for sensitive source materials and reduced batch cycle times

- Automated Handling options including single wafer transfer, assisted calotte load or full robot load or the calotte and transfer to the coating chamber from fontend cassettes

Step 4: Benefit from Evatec's Unicalc Solutions

Whatever configuration you choose, all our BAK family members come with 50 years of process know-how. Evatec Unicalc solutions for shaper optimization at the smallest dimensions are a perfect way to increase deposition rates for higher throughput and reduce material usage for critical processes using precious metals. To find out more about Unicalc click here.

Step 5: Download the BAK Family brochure

To get the complete overview about the BAK Family download the brochure or visit the news section of our website.

Got a BAK already ?

Do you want to extend the life of your existing BAK with new process capabilities or the latest modern control systems? Click here to download our retrofit brochure.

Step 1: Check what system capacity you need

Start by selecting a basic platform size according to your substrate size and preferred batch capacity for standard calotte handling. Click here to view a capacity chart for different system sizes.

Step 2: Choose your sources, accessories and process control technologies

To take a quick look at our portfolio of sources and process accessories click here - from effusion cells and digital beam sweep electron beam guns, to chamber heating and plasma sources for PIAD.

To read more about Evatec advanced process control technologies including quartz and optical monitoring click here

Step 3: Customize your BAK according to your processes and fab integration requirements

Investigate further custom options to build a BAK that’s just right for you.

- "Lift Off" platforms with extended throw for zero side wall coverage

- "Split Chamber" platforms for sensitive source materials and reduced batch cycle times

- Automated Handling options including single wafer transfer, assisted calotte load or full robot load or the calotte and transfer to the coating chamber from fontend cassettes

Step 4: Benefit from Evatec's Unicalc Solutions

Whatever configuration you choose, all our BAK family members come with 50 years of process know-how. Evatec Unicalc solutions for shaper optimization at the smallest dimensions are a perfect way to increase deposition rates for higher throughput and reduce material usage for critical processes using precious metals. To find out more about Unicalc click here.

Step 5: Download the BAK Family brochure

To get the complete overview about the BAK Family download the brochure or visit the news section of our website.

Got a BAK already ?

Do you want to extend the life of your existing BAK with new process capabilities or the latest modern control systems? Click here to download our retrofit brochure.