Plasma box

Choose Plasmabox for pinhole free, high purity films and simple reactor maintenance

Test Modal

Ullenda voluptaspe natem. Ceped quam rem. Nemped que porehen ihilitatis quas endest etur alis as id quatium expelic imoluptatur repe dendere ribus, sam nonserferum nessit que vel maxim re porro od quam dolo dusaectore aperuptae qui volore, comnisquo tem incto blacepu digniet pra dit labo. Tis aspid et everfer ovidestis derro tem sedis eicabo. Optaspe rferia volesenes erro quam, sitatus solut quiatum res same atem hitiam vento is videbit velit deror autatem.

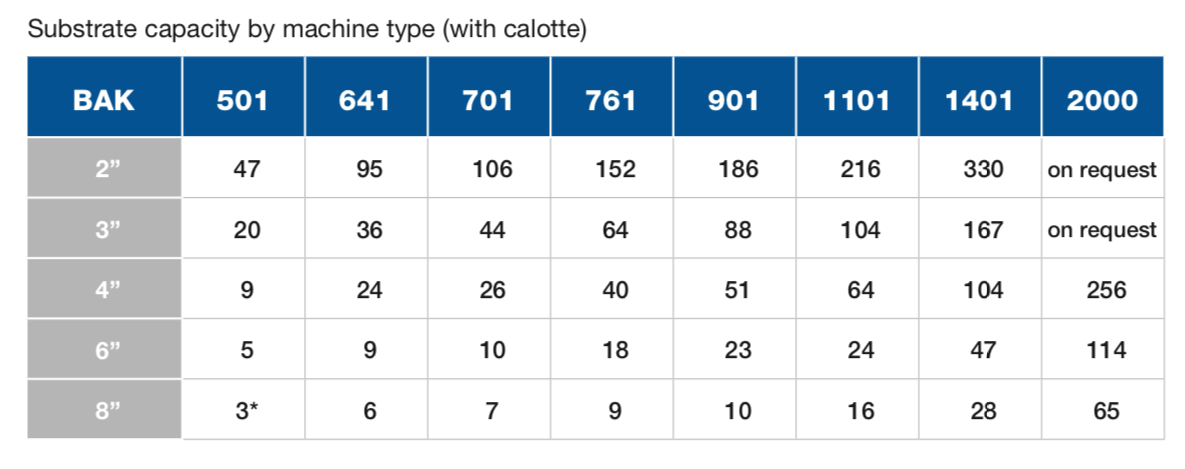

From the smallest to the biggest- get an idea how many substrates our systems can hold in a single batch

PLASMA-ENHANCED ATOMIC LAYER DEPOSITION (PEALD)

Thin films produced by sputter deposition can address various functionalities such as high optical transparency, defined electrical conductivity, and specific electromechanical properties like piezoelectric performance. These properties are easily achieved on flat and planar substrates. However, for non-planar surfaces, such as structured wafers and surfaces with small curvature radii, chemistry-based techniques provide solutions beyond line-of-sight.

Evatec’s new PEALD module integrated within the CLUSTERLINE® 200 family enables the deposition of thin dielectric film and opens up new possibilities for developing process flows using plasma etching, PVD and PECVD on one single platform without breaking vacuum.

This enables the seamless creation of layer stacks of various thin film materials, such as piezo-active systems with an oxide or nitride capping layer.

Are such combinations of various techniques missing in your tool portfolio? Does this versatile module fit into your existing CLUSTERLINE® 200 unit, or are you considering a cluster just with PEALD modules? We would be happy to discuss the various options with you!

Advanced Features and Applications

The PEALD module is equipped with a heatable substrate chuck, allowing temperatures up to 500°C. This opens new possibilities for post-deposition annealing without compromising the PEALD process. The system in its standard configuration provides two different metal precursor vessels, allowing the deposition of ternary films such as SrTiO3 , AlxGa1-xN, etc. with varying elemental ratios. The number of metal precursors can be adapted following customer’s requirements. Such configurations allow fabrication of ternary, quaternary and multilayer materials using supercycle approaches.

Why Evatec PEALD

Conformality, repeatability and high film thickness uniformity come as standard; the Evatec solution, providing a microwave plasma source, also reduces deposition temperatures, allowing the preparation of Al₂O₃, AlN films and others at near-room temperature. Microwave plasmas have very low sheath voltages, which is crucial for protecting ion radiation-sensitive materials.

Efficiency and Cost Reduction

The design of the module and processes is optimized to achieve minimal precursor consumption, thereby reducing costs of ownership. A special carrier configuration allows for double-sided deposition of substrates in a single run, maintaining the same layer thickness on both sides.

PEALD Platforms

PEALD technology is available on Evatec's production proven CLUSTERLINE® 200 platform.

Our experts are on hand to help you so please just contact us, if you have questions. Alternatively, click on the button to read more.

CLUSTERLINE® 200

Semiconductor industry standard cluster platform for 200mm single substrate processing integrating modules for ICP etch, PVD and PEALD.

Thin films produced by sputter deposition can address various functionalities such as high optical transparency, defined electrical conductivity, and specific electromechanical properties like piezoelectric performance. These properties are easily achieved on flat and planar substrates. However, for non-planar surfaces, such as structured wafers and surfaces with small curvature radii, chemistry-based techniques provide solutions beyond line-of-sight.

Evatec’s new PEALD module integrated within the CLUSTERLINE® 200 family enables the deposition of thin dielectric film and opens up new possibilities for developing process flows using plasma etching, PVD and PECVD on one single platform without breaking vacuum.

This enables the seamless creation of layer stacks of various thin film materials, such as piezo-active systems with an oxide or nitride capping layer.

Are such combinations of various techniques missing in your tool portfolio? Does this versatile module fit into your existing CLUSTERLINE® 200 unit, or are you considering a cluster just with PEALD modules? We would be happy to discuss the various options with you!

Advanced Features and Applications

The PEALD module is equipped with a heatable substrate chuck, allowing temperatures up to 500°C. This opens new possibilities for post-deposition annealing without compromising the PEALD process. The system in its standard configuration provides two different metal precursor vessels, allowing the deposition of ternary films such as SrTiO3 , AlxGa1-xN, etc. with varying elemental ratios. The number of metal precursors can be adapted following customer’s requirements. Such configurations allow fabrication of ternary, quaternary and multilayer materials using supercycle approaches.

Why Evatec PEALD

Conformality, repeatability and high film thickness uniformity come as standard; the Evatec solution, providing a microwave plasma source, also reduces deposition temperatures, allowing the preparation of Al₂O₃, AlN films and others at near-room temperature. Microwave plasmas have very low sheath voltages, which is crucial for protecting ion radiation-sensitive materials.

Efficiency and Cost Reduction

The design of the module and processes is optimized to achieve minimal precursor consumption, thereby reducing costs of ownership. A special carrier configuration allows for double-sided deposition of substrates in a single run, maintaining the same layer thickness on both sides.

PEALD Platforms

PEALD technology is available on Evatec's production proven CLUSTERLINE® 200 platform.

Our experts are on hand to help you so please just contact us, if you have questions. Alternatively, click on the button to read more.